Reyes Machinery

Reyes Machinery

Usually, we use HR Pusher centrifuge and LWL Horizontal screen worm centrifuge to separate salt.

Solid content processing capacity; The LWL series Horizontal screen worm centrifuge can be treated with a solid content of 20% -80%, but HR Pusher centrifuge cannot, which is basically around 30% -70%.

The higher solid content, the smaller difference between HR and LWL Salt Separation. If the solid content is not too high, and the demand for production is limited, and the budget is limited, choosing HR Pusher centrifuge single machine production is higher because the inflow flow can be faster.

There is no difference between two Salt Separation. Both are around 5%-7%.

We help customers choose screen mesh based on the required particle size.

The particle of LWL series Horizontal screen worm centrifuge is less than 200 mesh. And the HR Pusher centrifuge is less than 250 mesh.

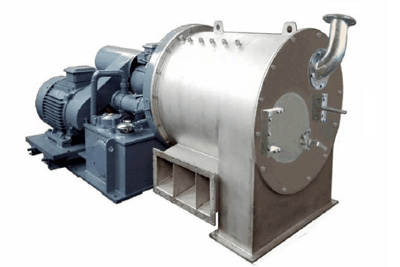

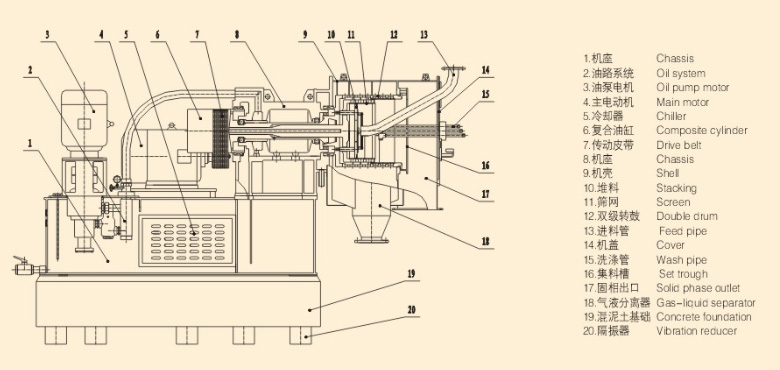

LWL screen worm centrifuge has been widely used in such industries as chemistry, food, salt, mining and pharmacy. Due to its separation principle and structural characteristics, it is mainly suitable for those materials with large particle size and without strict requirements on particles crushing. Therefore, it is required to conduct material analysis and relevant tests to determine the suitability and separation performance.

| Model | Bowl diameter (mm) | Bowl speed (r/min) | G-force (R/G) | Capacity (M³/H) | Mainmotor (Kw) | Weight (KGS) | Overall dimensions (L*W*H) |

|---|---|---|---|---|---|---|---|

| LWL200 | 200 | 4000 | 1790 | 0.5-1.5 | 3 | 550 | 1120*1020*800 |

| LWL 250 | 250 | 3500 | 1714 | 1.0-3.5 | 4 | 600 | 1120*1050*850 |

| LWL 320 | 320 | 2630 | 1240 | 0.5-2.5 | 7.5 | 700 | 1350*1050*1000 |

| LWL 350 | 350 | 3000 | 1770 | 1-3 | 11 | 1000 | 1400*1250*1150 |

| LWL 450 | 450 | 2500 | 1580 | 2-5 | 22 | 1500 | 1600*1400*1300 |

| LWL 530 | 530 | 2000 | 1190 | 3-10 | 30 | 2000 | 1700*1450*1400 |

| LWL 630 | 630 | 1800 | 1140 | 5-15 | 37 | 2500 | 2000*1440*1740 |

| LWL 800 | 800 | 1500 | 1006 | 8-30 | 55 | 3700 | 2750*1750*2000 |

| LWL 1000 | 1000 | 900 | 450 | 10-50 | 75 | 6200 | 3200*2155*2280 |

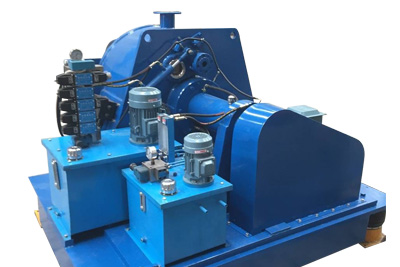

HR series industrial centrifuge of Two-stage piston pusher centrifuge is a continuous operation of the filter –type centrifuge. At full speed to comlete all of the operations processes:feeding,separation,washing,drying and unloding ,ect. Applied to the particles containing crystalline or short fibrous concentrated suspensions such as separation,widely used in chemical industry, salt pharmaceuticals, light industry and food industry, especially suitable for separation of solid phase material with particle size greater than 0.08mm,the concentration of more than 40% of the contained crystals or fibrous solids suspension of dehydration and solid-liquid speartion.

Applied Materials range: sodium chloride,ammonium chloride, potassium chloride,sodium sulfate,ammonium sulfate,potassium sulfate,urea,potassium carbonate,PVC,phosphate,nitrocellulose,cellulose acetate and so on.

| HR Industrial Centrifuge Two-stage piston pusher centrifuge | |||||

|---|---|---|---|---|---|

| Model : | HR300 | HR400 | HR500 | HR630 | HR 800 |

| Bowl inside diameter(mm) | 218/262 | 337/400 | 438/500 | 560/630 | 720/800 |

| Bowl length(mm) | 115/115 | 145/155 | 180/180 | 240/240 | 300/300 |

| Bowl rotation speed(r/min) | 2200 (Determined according to the use requirements) |

1500-2500 (Determined according to the use requirements) |

1200-2000 ( Determined according to the use requirements) |

1000-1800 ( Determined according to the use requirements) |

800-1600 ( Determined according to the use requirements) |

| Separation factor | 710 | 573-1083 | 402-1120 | 350-1142 | 268-1145 |

| Pushing stroke | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min |

| Feeding capacity per hour | 1-3t/h | 1-8t/h | 5-15t/h | 8-25t/h | 25-65t/h |

| Main motor power(kw) | 5.5KW | 11KW | 45KW | 55KW | 55-75KW |

| Auxiliary motor power | 3KW | 5.5 KW | 22KW | 30KW | 37KW |

| Outline dimension(mm) | 1550*800*710 | 2460*1286*1180mm | 3600*1420 *2078 MM | 3690*1600*1265 MM | 3700*1800*1450MM |

| Machine weight (kg) | 2480kg | 3500kg | 4100kg | 7000kg | |

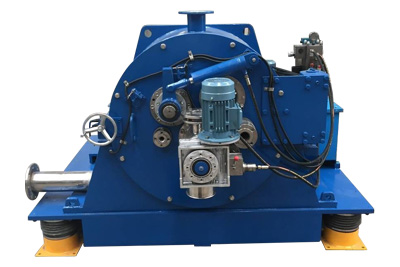

Siphonic Centrifuge is a type of full-automatic centrifuge with continuously working and batch operation. According to the structure, it can be divided into Siphonic Scraper Centrifuge (GKH series) and common scraper centrifuge (GK series).

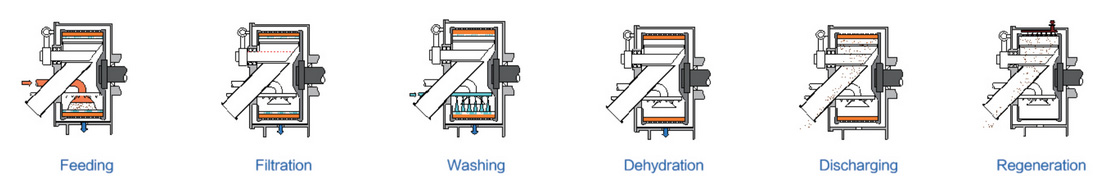

The scraper centrifuge can be switched between automatic and manual operation, so it can realize the periodic cyclic operation of feeding, dehydration, washing and discharging of the feed material.

Compared with common scraper centrifuge, the sophonic scraper centrifuge has siphonic force like vacuum, so it has better production capacity and separation effect. Especially, it is suitable for the feed material which has small solids, high viscosity, slow filtration and that needs to wash the filter cake.

GK Peeler centrifuge fully automatic centrifuge is a solid-liquid separation equipment that uses continuous operation and intermittent discharge. The machine is controlled by a programmable logic controller. The frequency converter is used for speed regulation, and the braking system adopts dynamic braking and regenerative braking. Through programs such as product level detection, speed, detection, shaft temperature and vibration monitoring, the entire separation process is an automatic cycle operation (including feeding, dehydration, washing, discharge, etc.

GKH Horizontal Peeler Siphon Centrifuge separation is superimposed by centrifuge force and siphon power, Production capacity can be increased by 50% or so while filtration driving force increases and separation time cuts down. Furthermore, significantly reduce the moisture content of the residues. As the drum did not have holes that it allows materials deposit, finally write liquid pipe removes clear liquid. This works quite well for the subtle materials which are difficult to separate. Due to the special features of siphon centrifugal, it's more extensively used in medicine, food, environmental protection, chemical and other industries

• PLC control, easy maintenance and operation.

• Action elements with automatic electric-pneumatic/hydraulic control.

• Safety protection.

• Welded machine case, strong and rationally design structure.

• All seals are made of the fluorous rubber and silicon rubber.

• Independent hydraulic station can be installed separately, convenient to repair.

• Stable start-up and simple control, effectively protecting the motor from overload-related damage. Optional inverter start-up for variable speed control.

• Liquid -damping vibration absorber is also available with excellent effects of absorbing effects, ensures stable operation.

• Two discharging modes available.

| Model & Parameter | ||||

|---|---|---|---|---|

| Item/Type | GK/GKH800-N | GK/GKH1050-N | GK/GKH1250-N | GK/GKH1600-N |

| Drum diameter(mm) | 800 | 1050 | 1250 | 1600 |

| Drum length (mm) | 450 | 500 | 600 | 1000 |

| Drum volume (L) | 100 | 165 | 355 | 830 |

| Loading capacity (Kg) | 150 | 290 | 500 | 1050 |

| Drum speed (r/min) | 1550 | 1350 | 1200 | 950 |

| Maximum separation factor | 1070 | 1020 | 1006 | 799 |

| Motor power (Kw) | 30 | 45 | 55 | 90 |

| Size (mm) | 2030*1960*1530 | 2430*1980*1800 | 2685*2300*1900 | 4050*2745*2295 |

| Weight (Kg) | 5500 | 7900 | 10500 | 16550 |

Have Any Questions !