Reyes Machinery

Reyes Machinery

Industrial centrifuges are categorized into two main categories: Filtration and Sedimentation.

A filtration centrifuge uses a rotating basket with small openings that allow liquid to drain through the basket but keep the solids. There are a variety of filtering centrifuges such as:

Perforate Basket Centrifuge (Batch Basket Centrifuge) for Hemp Washing with Ethanol The HHP series of centrifuges can be used for extracting and filtering centrifuges for cannabis and other plants. The series of centrifuges extract the active ingredients in plants through a built-in program, which is single-handed, easy to use and large in capacity. The machine adopts a closed structure, and the seal is sealed with PTEF; the explosion-proof motor, frequency converter, PLC, touch screen and other devices can be used to achieve the sealed explosion-proof requirements.

• Explosion-proof Motor

• Viton Seals

• Touch screen panel with PLC program

• Inverter control box

• On spot ex button

• Closed type filter bags

• Tri clamp fittings for feed and drain port

• Drum without curl inward Standard Features 304 and 316L Sanitary Stainless Steel Constructio Low temperature rating:-70℃

| Model | Drum diameter (mm) | Drum height (mm) | Volume (L) | Revolving speed (r/min) | Motor Power (KW) | Size (mm) | Weight (KG) |

|---|---|---|---|---|---|---|---|

| HHP-15 | 300 | 250 | 15 | 2000 | 1.1 | 1100*550*1020 | 230 |

| HHP-25 | 300 | 350 | 25 | 2000 | 1.5 | 1100*600*1020 | 265 |

| HHP-45 | 450 | 300 | 45 | 1500 | 2.2 | 1400*850*1080 | 400 |

| HHP-60 | 450 | 400 | 60 | 1500 | 3 | 1400*850*1080 | 470 |

| HHP-85 | 600 | 300 | 85 | 1250 | 3 | 1500*900*1080 | 970 |

| HHP-115 | 600 | 400 | 115 | 1250 | 4 | 1500*900*1100 | 1000 |

| HHP-145 | 600 | 500 | 145 | 1250 | 5.5 | 1500*900*1150 | 1030 |

• HHP-15 Charge per batch around 5Kg(10 pound) Amount of ethanol each time around 30L(8 gallon)

• HHP-25 Charge per batch around 8Kg(18 pound) Amount of ethanol each time around 40L(11 gallon)

• HHP-45 Charge per batch around 14kg(30pound) Amount of ethanol each time around 85L(23 gallon)

• HHP-60 Charge per batch around 20kg(45pound) Amount of ethanol each time around 105L(28 gallon)

• HHP-85 Charge per batch around 25kg(55pound) Amount of ethanol each time around140L(37 gallon)

• HHP-115 Charge per batch around 35kg(75pound) Amount of ethanol each time around175L(46 gallon)

• HHP-145 Charge per batch around 45kg(100pound) Amount of ethanol each time around 210(55gallon)

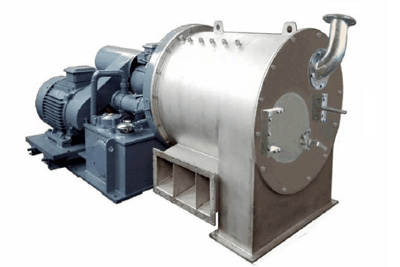

HR series industrial centrifuge of Two-stage piston pusher centrifuge is a continuous operation of the filter –type centrifuge. At full speed to comlete all of the operations processes: feeding, separation, washing, drying and unloding, ect. Applied to the particles containing crystalline or short fibrous concentrated suspensions such as separation,widely used in chemical industry, salt pharmaceuticals, light industry and food industry, especially suitable for separation of solid phase material with particle size greater than 0.08mm,the concentration of more than 40% of the contained crystals or fibrous solids suspension of dehydration and solid-liquid speartion.

Applied Materials range: sodium chloride, ammonium chloride, potassium chloride, sodium sulfate, ammonium sulfate, potassium sulfate, urea, potassium carbonate, PVC, phosphate, nitrocellulose, cellulose acetate and so on.

| HR Industrial Centrifuge Two-stage piston pusher centrifuge | |||||

|---|---|---|---|---|---|

| Model : | HR300 | HR400 | HR500 | HR630 | HR 800 |

| Bowl inside diameter(mm) | 218/262 | 337/400 | 438/500 | 560/630 | 720/800 |

| Bowl length(mm) | 115/115 | 145/155 | 180/180 | 240/240 | 300/300 |

| Bowl rotation speed(r/min) | 2200 (Determined according to the use requirements) |

1500-2500 (Determined according to the use requirements) |

1200-2000 ( Determined according to the use requirements) |

1000-1800 ( Determined according to the use requirements) |

800-1600 ( Determined according to the use requirements) |

| Separation factor | 710 | 573-1083 | 402-1120 | 350-1142 | 268-1145 |

| Pushing stroke | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min |

| Feeding capacity per hour | 1-3t/h | 1-8t/h | 5-15t/h | 8-25t/h | 25-65t/h |

| Main motor power(kw) | 5.5KW | 11KW | 45KW | 55KW | 55-75KW |

| Auxiliary motor power | 3KW | 5.5 KW | 22KW | 30KW | 37KW |

| Outline dimension(mm) | 1550*800*710 | 2460*1286*1180mm | 3600*1420 *2078 MM | 3690*1600*1265 MM | 3700*1800*1450MM |

| Machine weight (kg) | 2480kg | 3500kg | 4100kg | 7000kg | |

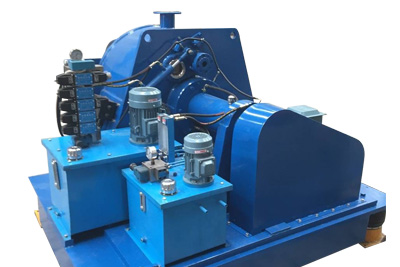

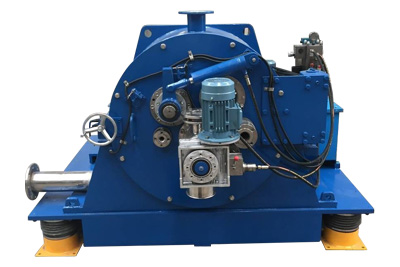

Siphonic Centrifuge is a type of full-automatic centrifuge with continuously working and batch operation. According to the structure, it can be divided into Siphonic Scraper Centrifuge (GKH series) and common scraper centrifuge (GK series).

The scraper centrifuge can be switched between automatic and manual operation, so it can realize the periodic cyclic operation of feeding, dehydration, washing and discharging of the feed material.

Compared with common scraper centrifuge, the sophonic scraper centrifuge has siphonic force like vacuum, so it has better production capacity and separation effect. Especially, it is suitable for the feed material which has small solids, high viscosity, slow filtration and that needs to wash the filter cake.

GK Peeler centrifuge fully automatic centrifuge is a solid-liquid separation equipment that uses continuous operation and intermittent discharge. The machine is controlled by a programmable logic controller. The frequency converter is used for speed regulation, and the braking system adopts dynamic braking and regenerative braking. Through programs such as product level detection, speed, detection, shaft temperature and vibration monitoring, the entire separation process is an automatic cycle operation (including feeding, dehydration, washing, discharge, etc.

GKH Horizontal Peeler Siphon Centrifuge separation is superimposed by centrifuge force and siphon power, Production capacity can be increased by 50% or so while filtration driving force increases and separation time cuts down. Furthermore, significantly reduce the moisture content of the residues. As the drum did not have holes that it allows materials deposit, finally write liquid pipe removes clear liquid. This works quite well for the subtle materials which are difficult to separate. Due to the special features of siphon centrifugal, it's more extensively used in medicine, food, environmental protection, chemical and other industries

• PLC control, easy maintenance and operation.

• Action elements with automatic electric-pneumatic/hydraulic control.

• Safety protection.

• Welded machine case, strong and rationally design structure.

• All seals are made of the fluorous rubber and silicon rubber.

• Independent hydraulic station can be installed separately, convenient to repair.

• Stable start-up and simple control, effectively protecting the motor from overload-related damage. Optional inverter start-up for variable speed control.

• Liquid -damping vibration absorber is also available with excellent effects of absorbing effects, ensures stable operation.

• Two discharging modes available.

| Model & Parameter | ||||

|---|---|---|---|---|

| Item/Type | GK/GKH800-N | GK/GKH1050-N | GK/GKH1250-N | GK/GKH1600-N |

| Drum diameter(mm) | 800 | 1050 | 1250 | 1600 |

| Drum length (mm) | 450 | 500 | 600 | 1000 |

| Drum volume (L) | 100 | 165 | 355 | 830 |

| Loading capacity (Kg) | 150 | 290 | 500 | 1050 |

| Drum speed (r/min) | 1550 | 1350 | 1200 | 950 |

| Maximum separation factor | 1070 | 1020 | 1006 | 799 |

| Motor power (Kw) | 30 | 45 | 55 | 90 |

| Size (mm) | 2030*1960*1530 | 2430*1980*1800 | 2685*2300*1900 | 4050*2745*2295 |

| Weight (Kg) | 5500 | 7900 | 10500 | 16550 |

A sedimentation centrifuge is a bowl with no openings, unlike the filtration centrifuge. Using centrifugal force, the solids accumulate along the bowl wall, while the liquid separates from the solid. After the liquid separates from the solids, it exits through an outlet passage. There are a variety of sedimentation centrifuges such as:

| Model | Diameter (mm) | Length (mm) | Max speed | L/D ratio | G-force | Capacity (m3/h) | Main motor power (Kw) | Weight (kg) | Dimension (mm) |

|---|---|---|---|---|---|---|---|---|---|

| LW/LWS250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 1600 | 2120*1250*680 |

| LW/LWS 300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1900 | 2150*1300*900 |

| LW/LWS 300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 2700 | 2450*1300*900 |

| LW/LWS 355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 2750 | 2470*1350*830 |

| LW/LWS 355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 2850 | 2750*1350*830 |

| LW/LWS 400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 3100 | 2730*1600*1080 |

| LW/LWS 400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 3260 | 3130*1600*1080 |

| LW/LWS 450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 3250 | 3320*1700*1130 |

| LW/LWS 500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

| LW/LWS 530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

| LW/LWS 530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

| LW/LWS 550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

| LW/LWS 650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

| LW/LWS 650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

| LW/LWS 720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

| LW/LWS 720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

| LW/LWS 800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

| LW/LWS 800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

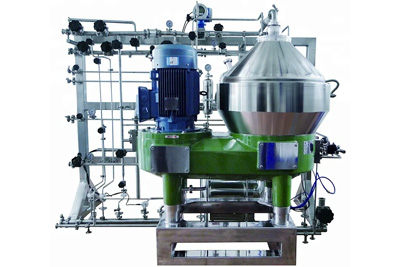

Disk stack centrifuge (disc separator ) can realize liquid-solid separation ,It is be used in the solid content of 1-15%, solid particles diameter is larger than 0.5 microns suspension liquid-solid. Disk stack centrifuge (disc separator )has better separation. It can be operated manually or automatically or remotely with PLC control to timer the process of working and solid discharge to save lots of labour work. It is simple in structure and easy in maintenance.

Disc stack centrifuge is widely used for many industries, such as dairy, beverage, food ,pharmacy, chemicals, petrol, metallurgy and biology, etc.

Especially biopharmaceutics as a high-technology has opened up a broad foreground for the development of medical industry and pharmaceutical industry and greatly improved people's lives.

The separation quality plays an important role in biopharmaceutical process.

Reyes machinery with its rich experiences in separation technologies aim at material extraction and purification during production of antibiotics, alkaloids and hormone,Vaccine, separation and purification of cell proteins as well as blood plasma separation.

| Model | Capacity (L/h) |

Drum diameter (mm) |

Drum speed (r/min) |

G-force | Power (KW) |

Weight (kg) |

Dimension (mm * mm * mm) |

| DHC/Z230 | 1500 | 230 | 6930 | 6170 | 2.2 | 240 | 850X625X985 |

| DHC/Z300 | 2000 | 300 | 7200 | 6950 | 4 | 550 | 865X645X1100 |

| DHC/Z 360 | 3000 | 360 | 6500 | 7000 | 5.5 | 650 | 900X600X1150 |

| DHC/Z400 | 4000 | 400 | 6500 | 7500 | 7.5 | 750 | 1100X1050X1250 |

| DHC/Z500 | 8000 | 500 | 5800 | 8500 | 18.5 | 1200 | 1250X1000X1550 |

Reyes Tubular Centrifuge is a high speed separation & clarification machine for continuous separation of two immiscible liquids with density difference. This tubular bowl centrifuge is also used to separate small quantity of impurities from liquids.

• Pharma

• Chemical

• Food Industries

• Edible Oil Industries

• Printing Ink

• Bacteria Cell Separation

• Gum Clarification

• Biodiesel Plants

• Beverage Industry

• Biomass Separation

GQ Tubular centrifuge separator is mainly used for separating all kinds of suspension which is difficult to be separated,especially suitable for separation of solid-liquid suspension with light concentration, heavy viscosity, fine particles and very small differential gravity of the two phases. such as clarification of herbs & plants extracts,various medicine liquor ,liquid medicine, wine clarify oral liquid, the extraction of paint, dye, as well as various proteins, alga,fruit gels, and purification of rubber solution, coal tar,graphite,saponin, milk,pectin, sirup, vaccine mycelia and all kinds of glucose; refining resin, spore and latex solution, enzyme (SOD) of oxide, various kinds of albumens, the glucoside of the soap,etc.

The tubular centrifuge separator is the equipment that works with high separation factor and capacity, little space and easy operation, with low noises, it is extremely convenient to maintain.

| Items | Models | ||||

|---|---|---|---|---|---|

| GQ75 | GQ105 | GQ125 | GQ150 | ||

| Bowl | Diameter (mm) | 75 | 105 | 125 | 150 |

| TheEffectiveHeight (mm) | 450 | 730 | 730 | 730 | |

| Bowl Volume (L) | 2.2 | 6 | 8 | 10 | |

| Speed ofRotation (r/min) | 19200 | 16300 | 15000 | 14000 | |

| SeparationFactor (ω2.r/g) | 15600 | 15250 | 15750 | 14300 | |

| Working pressure (MPa) | ≥0.05 | ||||

| Through Output Capacity for Clean Water (L/h) | 600 | 1200 | 2000 | 3000 | |

| Motor Power (kW) | 1.5 | 3.0 | 4.0 | 4.0 | |

| Dimensions(L×W×H) (mm) | 760 x 450 x1120 | 840× 500×1600 | 900× 550×1600 | 900× 550×1600 | |

| Weight (Kg) | 200 | 570 | 610 | 665 | |

GF Tubular Centrifuge Separator is used for separating various kinds of liquids that are difficult to be separated, especially suitable for liquid-liquid separation and liquid-liquid-solid separation.

It is a high-speed centrifuge with strong separating capacity. The bowl of the centrifuge rotates around its axis and forms a strong centrifugal force, the centrifugal force separates the suspensions into liquids and solid.

The suspension is fed through the bottom into the hollow cylindrical rotor which has two outlets at the top to allow the discharge of the separated liquids. The lighter liquid and the heavier liquid will flow out from the respective liquid outlets. At the same time the solids are deposited on the bowl's wall and the accumulated solids are cleaned out manually from the bowl when the centrifuge is shut down.

The parts contact with the material is made of stainless. The machine body can be stainless or iron casted with painting according to the material to be separated or the requirement of the customer.

The capacity of the tubular centrifuge separators is from 10L/h to 3000L/h depending on the different type of the tubular centrifuges and the density of the mixture to be separated.

| Items | Models | ||||||

|---|---|---|---|---|---|---|---|

| GF75 | GF105 | GF125 | GF150 | ||||

| Bowl | Diameter (mm) | 75 | 105 | 125 | 150 | ||

| TheEffectiveHeigh (mm) | 450 | 730 | 730 | 730 | |||

| Volume (L) | 2.2 | 6 | 8 | 10 | |||

| SpeedofRotation (r/min) | 19200 | 16300 | 15000 | 14000 | |||

| SeparationFactor (ω2.r/g) | 15600 | 15250 | 15750 | 14300 | |||

| Workingpressure (MPa) | ≥0.05 | ||||||

| Through Output CapacityforClean Water (L/h) | 500 | 1200 | 2000 | 2500 | |||

| MotorPower (kW) | 1.5 | 3.0 | 4.0 | 4.0 | |||

| Dimensions (L×W×H)(mm) | 760x450x1120 | 840×500×1600 | 900×550×1600 | 900×550×1600 | |||

| Theweight (Kg) | 300 | 570 | 610 | 665 | |||

The main difference between the two types of industrial centrifuges is the bowl design. The filtration centrifuge has a pass-through bowl, while the sedimentation centrifuge has a solid bowl. Other differences are separation efficiency, centrifugal force rate, and overall centrifuge design.

Industrial centrifuges can be used in a variety of processing and manufacturing industries. It can be used in industries such as:

• Refining

• Energy

• Oil

• Industrial Wastewater

• Pulp and Paper

• Chemical

• Wastewater Treatment Plants

Have Any Questions !